Let's get one thing straight right away: manufactured stone isn't some cheap plastic imitation. It’s a cleverly engineered, concrete-based material that perfectly captures the look, feel, and rugged character of natural stone. Think of it this way: it’s like a stunning, high-resolution photograph of a mountain range. It delivers all the visual impact and emotion of the real thing, just in a more accessible format.

So, What Exactly Is It?

At its heart, manufactured stone is a composite material, often called stone veneer. It's designed to give you the timeless, rustic beauty of natural stone but without the headaches—like the extreme weight, high cost, and tricky installation.

It’s made from a carefully calibrated recipe of cement, lightweight natural aggregates, and mineral oxide pigments for rich, authentic color. This mixture is then poured into molds that were cast from actual stones, which is how it captures every last nook, cranny, and subtle texture of the real deal.

The final product is often so convincing it’s hard to tell the difference between it and quarried stone. The real magic is in the manufacturing process, which gives you a level of consistency and predictability you just can't get when pulling stone out of the ground. For a deeper dive into similar engineered materials, this What Is Engineered Stone: A Homeowner's Guide is a fantastic resource.

To give you a quick snapshot, here are the core characteristics of manufactured stone.

Manufactured Stone At a Glance

| Characteristic | Description |

|---|---|

| Composition | A precise blend of cement, lightweight aggregates, and mineral oxides. |

| Weight | Significantly lighter than natural stone, typically 8-12 lbs per square foot. |

| Appearance | Meticulously crafted to replicate the authentic texture and color of real stone. |

| Installation | Easier and faster to install; does not require foundational footings. |

| Cost | More budget-friendly than quarried stone in both material and labor costs. |

| Versatility | Ideal for both interior and exterior applications, from facades to fireplaces. |

Ultimately, manufactured stone is all about providing a practical, beautiful alternative for homeowners and builders.

Why Was It Even Created?

The whole point of manufactured stone is to make the sought-after look of stone masonry available to everyone. It breaks down the barriers—both structural and financial—that have traditionally put natural stone out of reach for many projects.

Since it’s so much lighter, weighing in at just 8 to 12 pounds per square foot, you can install it almost anywhere without needing to pour concrete footings or add special wall ties for support. That’s a game-changer.

This opens up a ton of creative possibilities:

- Stunning Accent Walls: Add a dramatic, textured focal point to a living room or entryway.

- Cozy Fireplace Surrounds: Get that classic rustic hearth or sleek modern look without hiring a stonemason.

- Beautiful Exterior Siding: Boost your home's curb appeal with the rich look of stone.

- Upgraded Outdoor Spaces: Build gorgeous outdoor kitchens, columns, and seating areas with far less labor.

And people are catching on. The market for manufactured stone veneer is booming—it was valued at around USD 2.76 billion in 2021 and is on track to hit USD 3.28 billion by 2025. North America is leading the charge, making up nearly 40% of that demand.

In short, manufactured stone brilliantly answers the question: How do we get the rugged, authentic beauty of stone without the back-breaking weight and budget-breaking cost? The answer lies in smart engineering and a touch of artistry. It’s the perfect bridge between the look you want and the practicality you need.

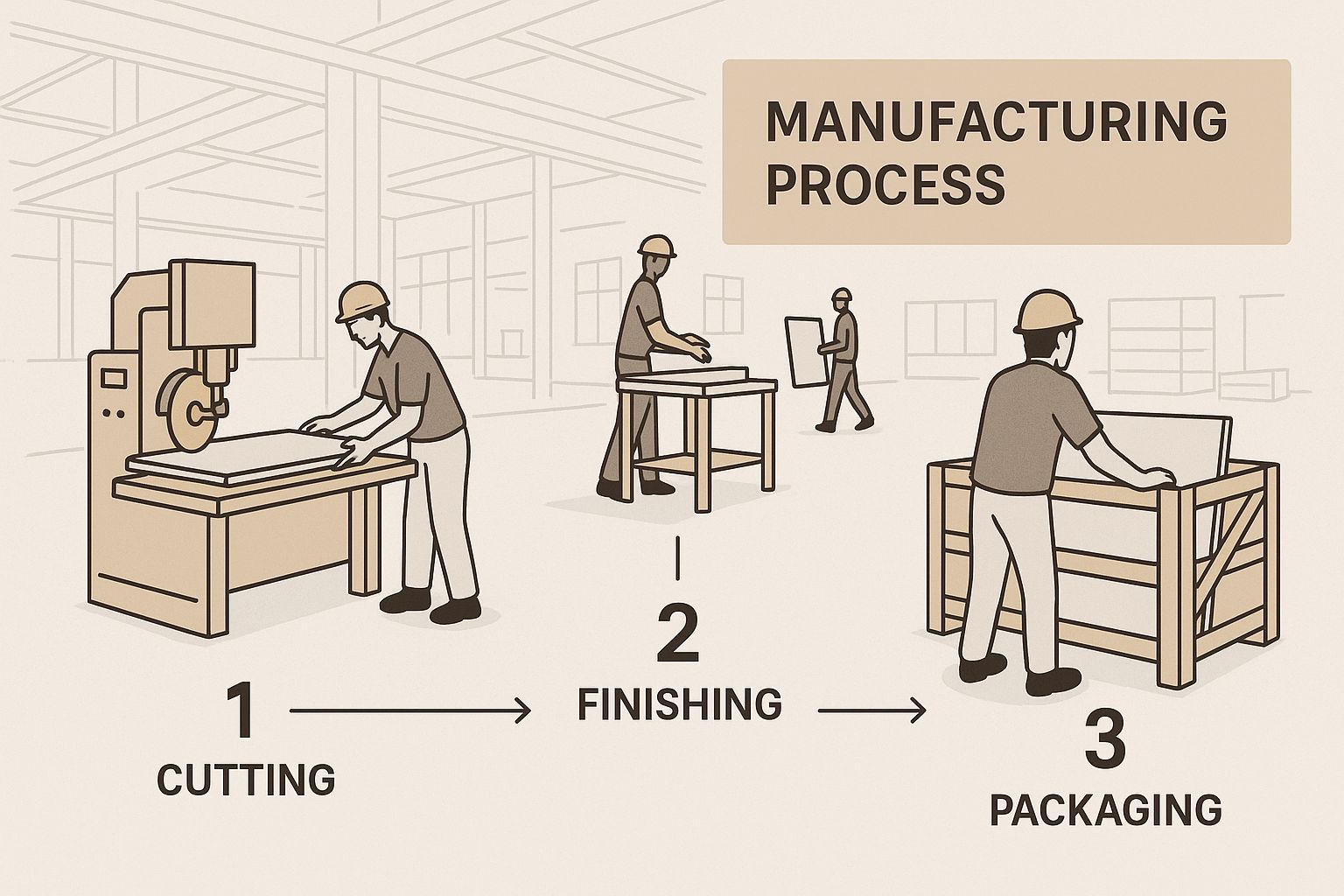

How Manufactured Stone Is Crafted

Turning a few simple, raw ingredients into a stone veneer that looks like it was pulled from an ancient quarry is a fascinating process. It’s far less of a sterile, automated assembly line and more like a sculptor's studio—a place where art and engineering meet. Understanding this hands-on process is the key to seeing why modern manufactured stone can be so incredibly convincing.

It all starts with an artist's touch. Before any machinery gets involved, artisans hunt for the perfect pieces of natural stone. They’re looking for stones with real character—the ones with interesting textures, deep-set cracks, and beautifully weathered faces. These hand-selected stones become the "masters," the original blueprints for every piece that will be made.

Creating the Perfect Molds

With the ideal natural stones chosen, the next step is to create molds that can capture their essence. These aren't just simple casts. They’re meticulously made from materials like latex or polyurethane, designed to pick up every tiny detail. Every subtle crevice, every fossil impression, and every worn-down edge is perfectly mirrored in the mold.

This isn't just a technical step; it's what separates a high-quality veneer from a flat, generic imitation. It ensures the final product has the same depth and texture as the original stone, giving it that authentic, believable character.

Blending the Core Ingredients

Once the molds are ready, it's time to mix the "dough." The core of manufactured stone is a carefully balanced recipe that delivers both an authentic look and incredible strength. The main components are:

- Portland Cement: This is the backbone of the mix, providing the structural integrity and durability that holds it all together.

- Lightweight Aggregates: Here’s the secret sauce. Materials like pumice, expanded shale, or clay are blended in. This dramatically reduces the stone's weight, making it much easier to handle and install without needing costly structural reinforcements.

- Mineral Oxide Pigments: To get those rich, earthy tones, natural iron oxide pigments are mixed directly into the concrete, providing the base color found in real stone.

As you can see, the process is a perfect marriage of precise blending and hands-on artistry, all aimed at creating a product that feels both consistent and naturally varied.

The Art of Hand Coloring

This is where the magic really happens. While the concrete mix is still wet in the molds, skilled artisans step in to hand-apply additional layers of mineral oxide pigments. They use different techniques—from dusting and spraying to delicate hand-painting—to create the subtle highlights, shadows, and color variations that make natural stone so beautiful.

This hands-on coloring is the single most important step in avoiding a repetitive, artificial look. By making sure no two stones are colored in exactly the same way, manufacturers achieve that organic, non-uniform appearance that makes the best manufactured stone nearly impossible to tell from the real thing.

Finally, the mixture cures in the molds, a process that hardens the material and permanently locks in the colors. This happens in a controlled environment to ensure every piece meets tough standards for strength and weather resistance—so tough, in fact, that many products come with warranties of up to 50 years. After curing, the stones are carefully demolded, inspected one last time, and packaged up, ready to add their timeless beauty to a new home or building.

Manufactured Stone vs. Natural Stone

When you’re staring down the decision between manufactured and natural stone, it can feel like a big one. Both materials bring a stunning, timeless look to any project, but they get there in very different ways. This isn't really about which one is "better"—it's about figuring out which one is the right fit for your budget, your timeline, and the specific look you’re trying to achieve.

To make that call with confidence, you have to look past the surface-level beauty and dig into the practical differences that will make or break your project. Let's put them head-to-head.

Cost and Installation Expenses

For most people, the budget is where the rubber meets the road. Natural stone is a premium product, and for good reason. It’s hewn directly from the earth, a process that demands heavy machinery, intensive labor, and costly transportation. All of that adds up.

This is where manufactured stone really shines. Because it’s created in a controlled factory setting, the process is far more efficient. The result? A material cost that's often 30% to 50% lower than its natural counterpart. The savings don't stop there, either. Installing heavy, irregular pieces of natural stone is an art form that requires a skilled mason, driving labor costs way up.

Manufactured stone, being lightweight and uniformly shaped, is a completely different story. It goes up faster and doesn't demand the same level of specialized skill, which translates into major savings on labor. When you're trying to nail down your budget, a good material cost predictor can show you just how significant these differences are.

Weight and Structural Requirements

This is probably the single biggest practical difference between the two. Natural stone is a heavyweight, often tipping the scales at 15 pounds per square foot or more. You can’t just stick that on any wall. Its immense weight means you almost always need to build a structural support, like a concrete footing or a brick ledge, to carry the load. That’s a serious, time-consuming, and expensive construction step.

Manufactured stone veneer, by design, stays under that 15 pounds per square foot threshold. This simple fact is a total game-changer. It means you can apply it directly to most standard, structurally sound walls without any extra engineering or foundational work.

This lightweight nature is what makes the classic stone look possible for so many more projects. It opens the door to interior accent walls, fireplace surrounds, and remodels where digging a new foundation just isn't an option.

Design Consistency and Variety

There's no denying the unique, one-of-a-kind beauty of natural stone. Every single piece is different, a snapshot of geological history. While that's part of its appeal, it can also be a headache. The color, pattern, and texture can vary dramatically from one quarry batch to the next, making it tough to get a consistent look across a large wall.

Manufactured stone, on the other hand, offers predictability. The colors and textures are carefully controlled during production, so the box you open today will match the box you open next month. This guarantees a cohesive look that's easy to plan around. You get all the visual appeal without any of the unwanted surprises.

Don't mistake consistency for a boring, repetitive look, though. The best manufacturers use hundreds of different molds and apply colors by hand to create a finished product that looks just as natural and varied as the real thing. To get an even deeper look, our guide on stone veneer vs natural stone breaks down the visual nuances in more detail.

Feature Showdown Manufactured Stone vs Natural Stone

Sometimes, the easiest way to see the difference is to line them up side-by-side. This table cuts right to the chase, comparing the key features that matter most to homeowners and builders.

| Feature | Manufactured Stone | Natural Stone |

|---|---|---|

| Material Cost | Lower, typically 30-50% less expensive. | Higher, due to quarrying and processing. |

| Installation Cost | Lower due to faster installation and less specialized labor. | Higher, requiring skilled masonry and more time. |

| Weight | Lightweight (under 15 lbs/sq. ft.). | Very heavy, requiring structural support. |

| Structural Needs | None needed; adheres to standard walls. | Requires foundational footings or ledges. |

| Design Consistency | Highly consistent color and texture. | Variable; each piece is unique. |

| Color Palette | Wide range of controlled, predictable colors. | Limited to what is found in nature. |

| Maintenance | Virtually maintenance-free; clean with mild soap. | May require periodic sealing to prevent staining. |

| Durability | Excellent, often warrantied for 50 years. | Extremely durable, lasts for centuries. |

So, what’s the final verdict? It all comes back to your priorities. If you crave that authentic, straight-from-the-earth feel and have the budget to support it, natural stone is an unbeatable choice. But if you’re looking for that same jaw-dropping aesthetic without the heavy price tag and structural gymnastics, manufactured stone delivers in spades.

Why Homeowners Choose Manufactured Stone

When you get right down to it, the choice to use manufactured stone comes from a powerful blend of smarts and style. The authentic look is what first catches your eye, but it’s the practical, real-world advantages that seal the deal for so many homeowners, architects, and builders. This isn't just about copying nature; it’s about making that timeless beauty more accessible and far more versatile for today's projects.

Manufactured stone solves the biggest headaches that come with using natural stone—namely, the budget-busting cost and the structural nightmares. It opens up a path to that high-end, custom look without the high-end price tag. Let's dig into the specific reasons it has become such a go-to material.

A Major Win for Your Budget

The most compelling reason people turn to manufactured stone is the cost. It’s a game-changer. You can realistically expect to slash your total project budget by 30% to 50% compared to what you’d spend on natural stone. And we're not just talking about the initial price tag on the material itself; the savings ripple through the entire project.

Here’s where that money stays in your pocket:

- The Stone Itself: Making stone in a factory is simply more efficient than blasting it out of a mountain and hauling massive, heavy slabs across the country.

- Shipping: It's a matter of weight. Since manufactured stone is so much lighter, the cost to transport it from the factory to your job site is significantly lower.

- Labor Costs: This is a big one. A mason can install manufactured veneer much faster because the pieces are lightweight and consistently shaped. Fewer hours on the clock means lower labor bills.

This financial break makes a huge difference. Suddenly, that stunning stone facade or cozy fireplace you’ve been dreaming of is well within reach, not just a luxury for unlimited budgets.

The real value of manufactured stone is that it democratizes premium design. It empowers you to achieve the exact look you envision without having to compromise your vision due to the extreme costs and logistical hurdles of natural stone.

Design Freedom Like Never Before

What if you could have stone in any shape, texture, or color you could imagine? That’s the reality with manufactured stone. You aren't limited by what a quarry happens to produce. Instead, you have a blank canvas.

This creative freedom means you can get a level of customization that’s impossible with quarried stone. Whether you want the rugged, chunky look of mountain ledge rock or the clean, smooth elegance of cut limestone, there’s a mold and color recipe for it. The pigments are mixed all the way through the stone, not just painted on the surface, so the color is rich, deep, and won’t fade away.

To see how this works in practice, you can explore the advantages and installation process of manufactured stone in our other guide.

An Installation Process That Just Makes Sense

Let’s be honest, installing natural stone is a beast of a job. It’s incredibly heavy, demands a highly skilled (and expensive) mason, and often requires pouring extra concrete footings just to support the weight.

Manufactured stone skips all that drama.

Because it typically weighs less than 15 pounds per square foot, you don't need to build special ledges or use wall ties to hold it up. It can be installed directly onto almost any solid surface—wood-framed walls, concrete, even old brick. This simple, straightforward process doesn't just save you time and money; it opens up a world of possibilities for projects where adding heavy-duty structural support would be a non-starter.

Inspiring Uses for Manufactured Stone

Knowing how manufactured stone is made is one thing, but seeing it in action? That’s where the magic really happens. The true beauty of this material isn't just in its components, but in its incredible versatility. It can completely remake a space, adding a sense of texture, character, and permanence that few other materials can pull off.

From dramatic exteriors that make you stop and stare to cozy interiors that invite you to settle in, manufactured stone offers a design palette that’s virtually limitless. Let’s dive into some of the most popular and inspiring ways it’s used to bring architectural visions to life, proving its mettle in both homes and businesses.

Boosting Curb Appeal with Exterior Magic

The outside of your home is its first impression, and manufactured stone is an absolute pro at making it a memorable one. Because it’s so much lighter than natural stone, it doesn't need extra foundational support. This is huge. It means you can add stunning visual interest without a massive, costly structural overhaul, making it a go-to for new builds and renovations alike.

Here are a few ways it makes a big impact outdoors:

- Full-House Siding: Wrapping an entire home in a rugged stone veneer creates a powerful, timeless statement. It can instantly elevate a standard house into what feels like a custom-built estate.

- Architectural Accents: You don’t have to go all-in to get a major effect. Applying stone to gables, entryways, or around windows adds a sophisticated depth that sets a home apart.

- Columns and Pillars: Covering porch columns or gate pillars in stone gives you a grand, welcoming entrance that feels both solid and incredibly elegant.

And it’s not just for looks. Manufactured stone is a workhorse in landscaping, too. You can learn more about how it’s used in projects like how to build retaining walls to see just how far its versatility extends.

Creating Stunning Interior Focal Points

Bringing manufactured stone inside is all about adding warmth, texture, and a touch of the outdoors. It's the perfect material for creating that one stunning feature that anchors an entire room's design. Whether your style is rustic farmhouse or sleek contemporary, there’s a stone profile out there that will fit perfectly.

The most classic interior use? The fireplace, hands down. A floor-to-ceiling stone surround can turn a simple firebox into a breathtaking centerpiece, creating a cozy spot that everyone naturally gathers around. It adds an immediate sense of history and permanence to any living room.

The true power of manufactured stone is its ability to elevate everyday spaces. An ordinary wall becomes a piece of art, a kitchen backsplash becomes a rustic feature, and a simple fireplace becomes the heart of the home.

Accent walls are another fantastic application. Picture a rugged, stacked stone wall behind the headboard in a master suite or lining a hallway for a bit of drama. That single design choice can define the entire feel of a space, adding a layer of texture that paint or wallpaper just can’t touch. This is a trick designers often use in commercial spaces, like restaurants and boutiques, to create an atmosphere that feels both inviting and high-end.

Versatility in Kitchens and Beyond

The kitchen is another space where manufactured stone really shines. A stone veneer backsplash, for instance, adds an organic, rustic element that contrasts beautifully with clean, modern cabinets and stainless steel appliances. It’s a great way to introduce texture without overwhelming the room.

In fact, engineered stone is a dominant force in kitchens and baths. Countertops are by far the largest application, accounting for more than 80% of engineered stone use in 2023. This boom is largely driven by homeowners wanting surfaces that stand up to real life—resisting stains from oils, wine, and coffee.

From wine cellars and basement bars to outdoor kitchens and poolside patios, the possibilities just keep going. The durability and weather-resistance of manufactured stone make it just as perfect for an outdoor living area as it is for a living room wall, giving you a beautiful, consistent material to weave throughout your entire property.

What to Know About Installation and Maintenance

You’ve decided on manufactured stone—a fantastic choice that adds incredible character and value. But to make sure that investment pays off for years to come, everything hinges on proper installation and a little bit of straightforward care.

Getting the installation right is more than just sticking stone to a wall; it’s a science. The process starts with painstakingly preparing the surface to ensure it’s clean, stable, and ready to form a lasting bond. From there, it's about building up layers: first a weather-resistant barrier, then a metal lath that gives the mortar something to grip onto.

Think of it like building a house—the foundation is everything. A "scratch coat" of mortar is spread over the lath and scored, creating a rough, grooved surface. This step is non-negotiable, as it’s what allows the final mortar coat and the stones to lock into place permanently.

The Keys to a Flawless Installation

Here's a hard truth: even the most beautiful, high-quality stone veneer will fail if it's not installed correctly. The single biggest culprit I see in failed jobs is poor water management. Water is relentless, and if it finds a way behind the veneer, you're looking at a recipe for serious damage.

A professional, long-lasting installation absolutely must include these three things:

- A Weather-Resistant Barrier: This is the primary shield protecting your wall sheathing from moisture.

- Proper Flashing: Meticulously installed around every window, door, and roofline, flashing is designed to actively direct water away from the wall.

- Weep Screeds: These are small but mighty components installed at the bottom of the wall. They’re designed to give any moisture that gets trapped behind the veneer an escape route.

If you want to dive deeper into the nuts and bolts of the process, our guide on stone veneer siding installation breaks it all down.

Simple Care for Lasting Beauty

One of the real perks of manufactured stone is just how easy it is to live with. For routine cleaning, a quick spray with a garden hose is usually enough. If you have some stubborn dirt, a soft-bristle brush and a little mild detergent will do the trick.

The golden rule of manufactured stone care is to be gentle. Never, ever use a pressure washer, a wire brush, or any kind of acid-based cleaner. These will absolutely wreck the stone's texture and can strip the color right out of it.

For long-term peace of mind, just give the mortar joints a quick look-over once a year. If you spot any small cracks or gaps, get them sealed up. It’s a simple, five-minute check that prevents water intrusion and keeps your stone looking perfect for decades.

Frequently Asked Questions About Manufactured Stone

As you get closer to choosing the right stone for your project, a few key questions probably come to mind. It's smart to have all the facts straight before you commit. Let's walk through some of the most common things people ask us, so you can move forward with total confidence.

Just How Tough Is This Stuff?

It’s incredibly tough. Manufactured stone is specifically engineered to stand up to the elements, from blistering sun to brutal freeze-thaw cycles that can destroy lesser materials.

While something like solid granite is technically harder, a quality stone veneer is built to last a lifetime and is often backed by a 50-year warranty. It’s designed to resist chipping and cracking from everyday life. Plus, because the color is mixed all the way through the material—not just painted on the surface—it won't fade or wear away. Your project will look just as stunning decades from now.

Can I Just Install This Myself?

Even if you’re a seasoned DIY pro, we almost always recommend hiring a professional for this one. The beauty and longevity of your stone veneer are completely dependent on what happens behind the scenes.

Proper moisture management—including the correct installation of water-resistant barriers, lath, and flashing—is non-negotiable. It's the only way to prevent water from getting trapped behind the stone, which can lead to serious, expensive structural damage. A botched installation will almost certainly void your warranty.

But Does It Look Fake?

This is the number one concern we hear, and the answer is simple: a high-quality product looks remarkably real. The best manufactured stone on the market today is virtually indistinguishable from the natural stone it mimics, even when you're standing right next to it.

How do they pull it off? It comes down to two things:

- Molds from Real Stone: The process starts with molds cast from hand-picked natural stones, capturing every tiny crevice, fossil print, and unique texture.

- Artisan-Applied Color: Skilled artisans hand-paint the stones in multiple layers, recreating the subtle, random color variations you'd find in a natural quarry.

The cheap stuff often gives itself away with repetitive patterns. That's why choosing a reputable manufacturer is the single most important decision you can make.

Ready to see how the right stone can completely transform your space? The experts at Flomary Group can guide you to the perfect ultra-thin stone veneer for your home or business. Contact us today for a free quotation and personalized consultation!

Article created using Outrank