The Science Behind Cement Board's Fire Resistance

Imagine holding a piece of wood and a piece of cement board over a flame. The wood, being organic, catches fire quickly, releasing gases that fuel the flames. But the cement board? It stays remarkably stable. This stark contrast comes down to their basic makeup. Cement board – a mix of sand, cement, and cellulose fibers – reacts to heat very differently than organic materials like wood. So, does that mean cement board is fireproof?

This inherent fire resistance comes from how it's made. The cement, sand, and cellulose fibers go through a process called hydration and curing. This creates a tough, non-combustible material. Think of it like baking a cake: the individual ingredients transform through a chemical reaction into something new and stronger. Similarly, the components of cement board bind together to form a material that doesn’t just tolerate heat—it actively resists burning. Interested in seeing some examples? Check out Flomary's concrete board options.

How the Ingredients Interact with Fire

Each ingredient in cement board plays a vital role in its fire-resistant properties. Cement, derived from limestone and clay, provides the binding strength and inherent non-combustibility. Sand acts as a filler and helps the board maintain its shape under high temperatures. The cellulose fibers, while organic, are encased within the cement and contribute to the board’s overall strength and flexibility. Because they're locked in this dense material, they have limited access to oxygen and don't readily ignite.

Furthermore, Cemintel, a leading Australian manufacturer of fiber cement products, highlights that their products are classified as non-combustible under the BCA (Building Code of Australia). This is a crucial distinction. It means fiber cement can be used in place of other non-combustible materials in construction. Discover more insights here. This reinforces the idea that cement board is designed to stop fire from spreading, providing essential protection for buildings. Understanding these fundamentals helps explain why cement board is such a popular choice in fire-prone regions.

Decoding Australian Fire Standards For Your Project

Navigating Australian fire safety regulations can feel like wandering through a maze. But understanding these standards is absolutely essential for constructing safe, compliant buildings. Let's break down the key elements, making them clear and practical for your next project.

Understanding "Non-Combustible"

The term non-combustible doesn't mean a material is fireproof. Instead, it signifies that the material won't add fuel to an existing fire. Imagine a steel beam in a fire. It won't ignite and burn like wood, but it will absorb heat and could eventually warp or buckle.

Cement board reacts similarly. It's considered non-combustible because it won’t catch fire and add to the blaze. This makes it a much safer choice compared to flammable materials like timber cladding.

The Importance of "Deemed-to-Satisfy"

The National Construction Code (NCC) uses the term Deemed-to-Satisfy for building solutions that automatically meet the code’s requirements. Opting for a Deemed-to-Satisfy solution, like using cement board in specific applications, simplifies compliance and can streamline the approval process.

Think of it like having pre-approval for a loan. It simplifies the process, reduces uncertainty, and provides assurance that your building project adheres to critical fire safety regulations.

Australian Fire Resistance Classifications

To help illustrate the various fire resistance levels within the Australian context, let's examine the following table. It breaks down the different classifications, their durations, typical applications, and how cement board fits into the picture.

| Classification Type | Fire Resistance Duration | Typical Applications | Cement Board Compatibility |

|---|---|---|---|

| Type A | 4 hours | Fire walls, structural elements | Highly Compatible |

| Type B | 2 hours | Load-bearing walls, floors | Compatible, often used in conjunction with other materials |

| Type C | 1 hour | Non-load-bearing partitions, ceilings | Compatible, offers good protection for these applications |

| Type D | 30 minutes | Some internal linings, limited structural applications | Can be used, but other materials may be more suitable for shorter durations |

This table summarizes the different levels of fire resistance you'll encounter and highlights how cement board can contribute to achieving those levels. Choosing the right classification is crucial for ensuring adequate protection.

AS 3959 and the NCC: Working Together

AS 3959 is the Australian Standard specifically for building in bushfire-prone areas. It works alongside the NCC, adding another layer of protection tailored to these high-risk zones. Understanding the interplay between these two standards is vital if you're building in bushfire-prone areas.

In Australia, the focus on fire-resistant materials has intensified, particularly after high-profile fires involving combustible cladding. The NCC plays a vital role in setting these standards, and fibre cement products are frequently chosen as a Deemed-to-Satisfy solution. Discover more insights.

Real-World Implications

Australian fire standards aren't just abstract rules; they are a direct response to real-world events and hard-learned lessons. These regulations exist to protect lives and property. By understanding the “why” behind the regulations, you can make more informed choices that prioritize fire safety without compromising your design or budget. This proactive approach builds a safer, more resilient built environment for everyone.

Inside The Fire Testing Lab: What Really Happens

Imagine walking into a lab where building materials are put through the wringer…literally. It's not a movie set, but a fire testing facility for materials like cement board. These tests show how materials react under intense heat, providing essential information for building codes and design choices.

The Anatomy of a Fire Test

Standardized tests, like the ASTM E119, expose materials to controlled but extreme heat. Picture a huge oven, steadily increasing in temperature while engineers carefully track the material's reaction. They're measuring how long the material can withstand the heat before it starts to break down structurally. It's not simply about whether it catches fire—it's about how well it holds its form and strength under pressure.

Some cement board systems, for example, can endure for two hours or longer, while others crumble much sooner. This variation depends on a few key factors:

- Thickness: A thicker board provides greater thermal mass, essentially acting as a more effective heat shield.

- Composition: The specific blend of cement, sand, and fibers impacts fire performance.

- Installation: Surprisingly, even with top-quality materials, improper installation can compromise fire resistance.

Real-World Performance vs. Lab Results

Lab tests give us valuable data, but real-world fires are far more complex. Factors like wind, surrounding temperature, and the presence of other flammable materials all affect how a fire spreads. However, lab testing provides a fundamental understanding of a material's inherent fire resistance. Understanding fire safety regulations is also important. For further information, you can research investment compliance and the Rule 506 C Guide.

Fibre cement boards in Australia have a solid reputation for fire resistance, especially vital in bushfire-prone regions. For example, James Hardie fibre cement products are known for their excellent early fire hazard properties and can provide up to two hours of fire resistance in certain wall systems. Learn more here.

Why This Matters

Understanding the science behind fire testing helps you make smarter choices for your building projects. Knowing how a material performs under controlled conditions allows for better risk assessment and stronger, safer structures. Whether you’re a homeowner, builder, or architect, this knowledge contributes to the safety of people and property. It’s about constructing buildings that can withstand even the most demanding situations.

Material Face-Off: How Cement Board Stacks Up

When a fire ignites, the materials composing your building become pivotal. Cement board, with its inherent fire resistance, provides a significant advantage. Let's explore how it compares to other common building materials like timber, vinyl, and metal cladding. Think of it like choosing armor for a battle against the flames – some materials offer robust protection, while others crumble under pressure.

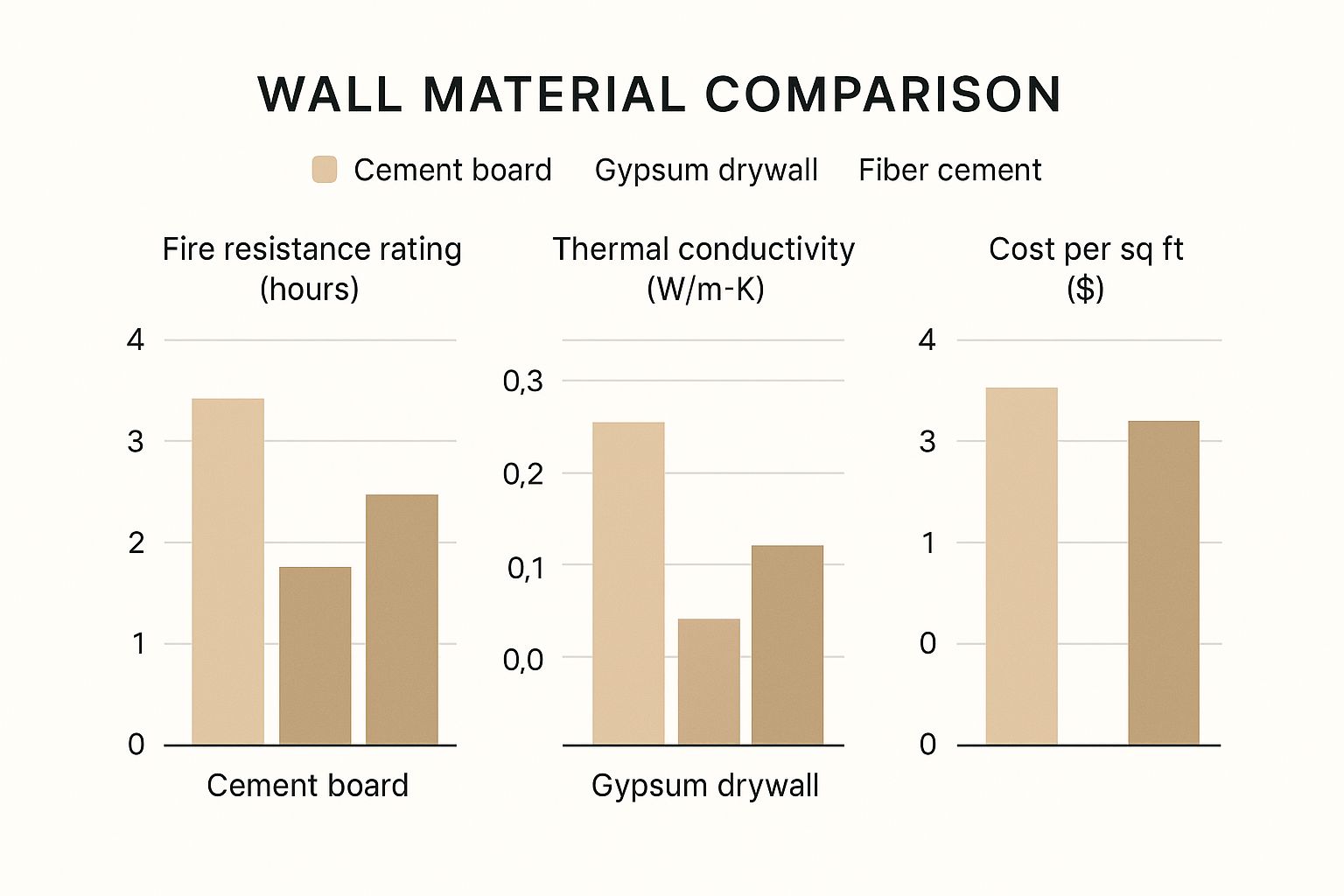

This infographic provides a snapshot of how cement board, gypsum drywall, and fiber cement measure up in terms of fire resistance rating, thermal conductivity, and cost per square foot. Notice how cement board strikes a balance between protection and affordability. It offers superior fire resistance compared to gypsum drywall and is often more budget-friendly than fiber cement.

Timber vs. Cement Board

Timber, a classic building material, has a significant weakness: it burns. While treated timber offers some increased fire resistance, it ultimately adds fuel to the fire. Imagine throwing a log onto an already raging bonfire. Cement board, however, is non-combustible. It acts like a shield, preventing the flames from spreading and buying precious time for evacuation and fire suppression.

Vinyl and Metal Cladding: A Closer Look

Vinyl cladding is often chosen for its cost-effectiveness, but it's like wrapping your house in plastic – it melts and burns quickly in a fire, releasing toxic fumes. Metal cladding, although non-combustible, can warp and buckle under intense heat, compromising the building's structural integrity. Picture a metal beam softening and twisting in a furnace. Cement board, on the other hand, maintains its shape and strength for much longer, providing a more reliable fire barrier.

Material Combinations: The Good and The Bad

The materials surrounding your cement board can significantly influence its fire performance. Pairing it with fire-resistant insulation is like doubling down on your defenses – creating a robust fire protection system. However, combining it with flammable materials can negate its protective qualities. It's like wearing a fire-resistant suit but carrying a tank of gasoline – a dangerous combination.

Let's take a look at how various building materials compare in terms of fire performance:

To illustrate this further, let's compare the fire performance of common building materials:

Fire Performance Comparison: Building Materials

| Material Type | Fire Rating | Ignition Temperature | Smoke Production | Cost Factor |

|---|---|---|---|---|

| Cement Board | High | Very High | Low | Medium |

| Timber (Untreated) | Low | Low | High | Low |

| Timber (Treated) | Medium | Medium | Medium | Medium-High |

| Vinyl Cladding | Very Low | Low | High | Low |

| Metal Cladding | High | Very High | Low | High |

| Gypsum Drywall | Medium | Medium | Medium | Low-Medium |

This table summarizes the key fire performance characteristics of these materials. As you can see, cement board excels in fire rating and smoke production, while also offering a reasonable cost.

Real-World Lessons Learned

Tragic events like the recent bushfires in Australia offer stark reminders of the importance of material choices. Homes clad in cement board often fared significantly better than those with timber or vinyl cladding. These real-world scenarios demonstrate that understanding the true fire performance of building materials is crucial. It's not about marketing hype, but about proven performance. Choosing the right materials can be the difference between minor damage and total devastation.

Surviving Australia's Fire Zones: Real Stories

Building a home in Australia's bushfire-prone areas presents unique challenges. Choosing the right materials is like selecting armor for a knight – it can mean the difference between withstanding a siege or succumbing to it. So, just how effective is cement board in protecting homes from the devastating impact of bushfires? Let's explore some real-world stories to find out.

Lessons From the Fireground

Recent bushfires have provided stark lessons about building resilience. Talking with those who've faced the flames – homeowners, builders, and firefighters – paints a clear picture: cement board cladding often acted as a critical shield. While no material is truly impervious to fire’s wrath, houses clad in cement board have consistently fared better than those with more flammable materials like timber. This emphasizes the essential difference between fire-resistant and fireproof.

For instance, imagine two neighboring houses in a fire-stricken area. One, clad in cement board, stands scarred but fundamentally sound. The other, clad in timber, is reduced to ashes. The cement board home, while damaged, retains its structural integrity, allowing for repair and rebuilding. This illustrates the power of cement board to lessen fire damage and preserve the skeletal framework of a home, offering a chance for recovery rather than complete loss.

Practical Strategies for Enhanced Fire Safety

Simply using cement board isn't enough. Think of it as a chain – its strength is determined by its weakest link. Proper installation is paramount to maximizing its protective qualities.

- Tight Joints and Sealing: Just as a knight's armor must have no gaps for a sword to penetrate, your cement board cladding needs tightly sealed joints. These prevent embers and flames from sneaking through cracks and compromising the structure.

- Fire-Resistant Fasteners: Even seemingly small components matter. Using standard screws is like using flimsy thread to hold together strong fabric – under intense heat, they can melt and fail. Fire-resistant fasteners, however, ensure the cladding remains firmly attached, even in extreme temperatures.

- Complementary Materials: A knight doesn't rely on armor alone; they also use a shield. Similarly, combine cement board with other fire-resistant materials like insulation and sealants. This multi-layered approach provides a comprehensive defense against fire.

Rebuilding With Resilience

Conversations with homeowners who’ve rebuilt after fires reveal a recurring theme: "We’d use cement board again." Many share stories of how it shielded sections of their homes, or even bought them precious time to salvage irreplaceable belongings. These firsthand accounts underscore the practical value of cement board in real-world fire scenarios. You might be interested in exploring Flomary's eco-friendly building materials for additional options.

These experiences and practical strategies offer invaluable guidance for anyone building or renovating in fire-prone areas. It’s about making informed decisions that prioritize safety and resilience. Choosing cement board is a step towards building a home that can better weather the storm of a bushfire. While the devastation these fires cause is undeniable, these stories also highlight the power of resilient building practices and the role of materials like cement board in protecting what matters most – lives and homes.

Installation Secrets For Maximum Fire Protection

Cement board is inherently fire-resistant, right? Well, yes, but even the toughest materials can underperform if not installed correctly. Think of it like a medieval suit of armor – incredibly strong, but useless if the pieces aren't fitted together properly. Let’s explore the critical installation details that can truly maximize cement board's fire protection.

Fastening For Fire Resistance

You might be tempted to use regular screws, but under intense heat, standard fasteners can soften and lose their grip. Imagine a chain breaking at its weakest link. In a fire, those screws are the weak link. That's why using fire-resistant fasteners is so important. These specialized screws are designed to maintain their strength even at high temperatures, keeping the cement board firmly in place when it matters most.

Sealing: The Unsung Hero

Any gaps or cracks in your cement board installation are like openings in that suit of armor. They provide a pathway for flames and embers to sneak through. That’s where proper sealing comes into play. Using fire-resistant sealant and joint tape creates a continuous, airtight seal, much like caulking a ship to keep water out. This airtight barrier stops fire from spreading behind the cement board.

Flashing Around Openings

Windows and doors are naturally vulnerable areas in a fire. Think of them as the weaker sections of a castle wall. Flashing around these openings with non-combustible materials is crucial. It reinforces these vulnerable points, preventing fire from bypassing the cement board and entering the structure.

Common Installation Mistakes and How to Avoid Them

-

Incorrect Fastener Spacing: If fasteners are spaced too far apart, the board’s resistance to heat and pressure weakens significantly. Always follow the manufacturer's recommendations for spacing and make sure screws are driven flush with the board surface.

-

Ignoring Joint Treatment: Untreated joints leave gaps, compromising the fire resistance. Taping and sealing these joints correctly is absolutely essential to create a continuous, fire-stopping barrier.

-

Using the Wrong Sealant: Regular sealants can melt under high heat, rendering them useless in a fire. Choose a fire-resistant sealant designed specifically for high-temperature applications.

Enhancing Fire Protection

Proper installation not only maintains cement board’s fire resistance, it can actually enhance it. Think of it as adding multiple layers of protection to that knight's armor – each layer contributes to the overall defense. Similarly, combining cement board with other fire-resistant materials, like insulation and intumescent coatings, creates a robust, multi-layered shield against fire. You might be interested in learning more about the manufactured stone benefits and installation.

By understanding these key installation points and avoiding common mistakes, you can ensure your cement board provides maximum fire protection, safeguarding your structure and those inside. These seemingly small details can make all the difference in a critical situation.

Your Fire-Safe Building Decision Framework

Armed with a deeper understanding of cement board's fire-resistant properties, you're now ready to put that knowledge to practical use. This section provides a framework for deciding if cement board is the right fit for your building project, balancing crucial fire safety with budget, aesthetics, and ongoing maintenance.

Balancing Fire Safety with Other Project Priorities

Is cement board truly fireproof? Not completely. Think of it like a really good raincoat – it'll keep you dry in a downpour, but you wouldn’t want to jump in a swimming pool with it. Cement board offers impressive fire resistance, making it a strong contender for many projects. But like piecing together a jigsaw puzzle, every building material must fit the big picture. Fire safety is a crucial piece, but not the only one.

-

Budget: Cement board often strikes a good balance between cost and protection. It's likely more expensive than flammable materials like wood, but generally less than specialized fireproofing systems. Consider it an investment in long-term safety and potential insurance savings down the road.

-

Aesthetics: Cement board is surprisingly versatile. It can be painted, textured, or serve as a base for various finishes, fitting seamlessly with many architectural styles. It's not just about function; it's about creating a space that looks great and performs well.

-

Maintenance: Cement board requires relatively little upkeep, resisting moisture, rot, and pests. This means fewer repairs and replacements over time, contributing to long-term cost savings and peace of mind. Safety during installation is also paramount. A rigging inspection checklist can be a helpful resource for ensuring a secure setup.

Steps for Confident Decision-Making

-

Assess Your Risk: Start by evaluating your location. Are you in a bushfire-prone area? Do local building codes require specific fire ratings? Understanding your risk level is like checking the weather forecast before a hike – it helps you pack the right gear.

-

Evaluate Alternatives: Compare cement board with other building materials. Consider their fire performance, cost, and how they fit with your design vision. This side-by-side comparison clarifies the trade-offs and empowers informed choices.

-

Consult with Professionals: Talk to architects, builders, and fire safety experts. They offer tailored advice based on your project and location, acting as experienced guides through the complexities of building regulations and fire safety requirements.

-

Plan for Long-Term Performance: Think ahead. Consider the material’s lifespan, maintenance needs, and how it interacts with other building components. A holistic approach, like considering all aspects of your health, ensures your fire protection strategy remains effective for years to come.

Moving Forward With Confidence

Whether building a new home or renovating an existing one, this framework empowers you to make confident decisions. It’s not just about checking boxes on an inspection form; it's about building with resilience and genuine peace of mind. By considering fire safety alongside other project priorities, you create a building that's both beautiful and protected.

Ready to discover how innovative stone products can enhance your project while prioritizing fire safety? Visit Flomary Group to explore our collection of ultra-thin stone veneer and flexible tiles, designed for beauty, durability, and peace of mind.