Why Everyone's Talking About Fireproof Building Materials

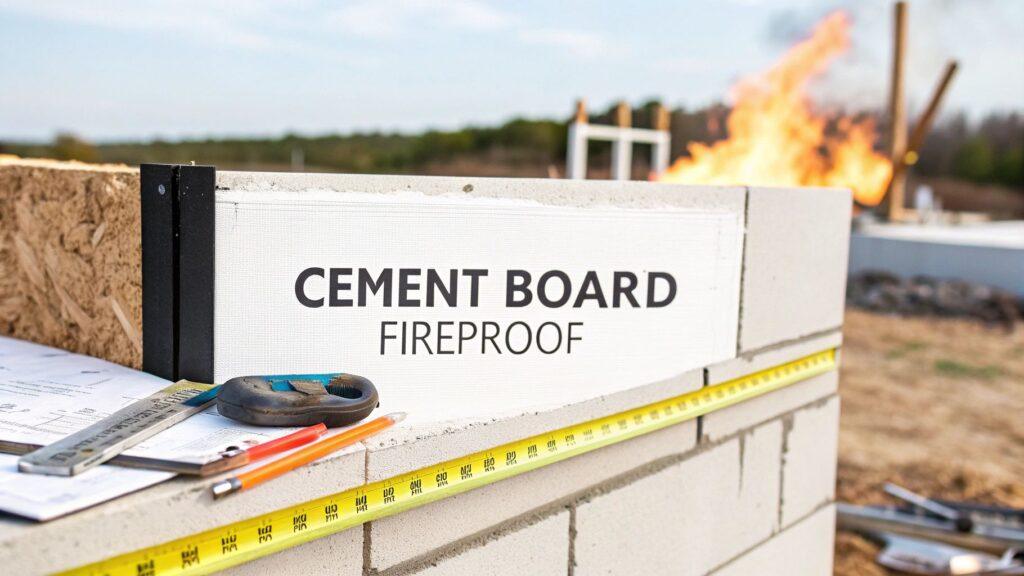

Imagine two houses side-by-side after a wildfire. One is still standing, scarred but strong. The other? Reduced to ashes. The difference often boils down to the building materials. Across Australia, builders are sharing stories of how cement board fireproof materials have saved homes, and lives. These aren't just stories, though. Insurance assessors confirm them, having witnessed the devastation firsthand on properties built with traditional, less fire-resistant materials.

Take, for example, a recent conversation I had with a contractor in Victoria. He described a house clad in cement board that survived a raging bushfire that leveled several neighboring properties. This wasn’t a miracle; it was the direct result of using a material designed to resist intense heat. These real-world examples are changing the building industry, pushing fire-resistant construction to the top of the priority list. Homeowners are asking better questions, demanding materials that offer more than just good looks.

This emphasis on fire safety isn't just about immediate protection, it's about the long-term. People who chose fire-resistant materials like cement board early on are seeing perks beyond safety, like lower insurance premiums and higher property values. A fire-resistant house is just a smarter investment—financially and emotionally. Fiber cement boards, in particular, are gaining traction in Australia for their fire-resistant properties and environmental sustainability. With increasing urbanization, especially in densely populated areas, fire safety in construction is paramount. Because they're non-combustible and can handle extreme temperatures without falling apart, fiber cement boards are being used more and more in facades, partition walls, and fire barriers. Discover more insights

When it comes to fire protection, planning is key. Learning from others’ experience can help you develop a solid strategy. For some guidance, check out these risk management framework examples. You might also find this resource on eco-friendly building materials useful. The shift towards prioritizing fire safety shows a growing understanding of the risks we face with traditional building methods in a changing climate. Choosing the right materials isn’t just smart—it’s essential.

Inside The Fire Shield: How Cement Boards Actually Work

Imagine a castle wall, stones packed tight, standing firm against a siege. That's a good way to picture how cement board resists fire. It's inherently strong and stable in extreme heat. But why? The secret lies in its molecular structure.

Cement boards are made of three key ingredients: Portland cement, aggregate, and reinforcing fibers. Think of the cement and aggregate as the mortar holding those castle stones together, but on a microscopic level. This creates a strong, inorganic matrix.

The reinforcing fibers, usually cellulose or glass mesh, are like tiny steel rods strengthening the "stones" from within. They add extra toughness and prevent cracking when things get hot. This powerful combination is the key to cement board's fire-fighting abilities.

The Science of Fire Resistance

What happens when a cement board meets fire? It's actually pretty interesting. The heat causes trapped water molecules in the cement matrix to evaporate.

This evaporation acts like a built-in cooling system. It absorbs a lot of the heat energy, keeping the board cooler and slowing the temperature rise. It’s similar to throwing water on a fire to extinguish it. This "cooling effect" is a big part of cement board's fireproof performance.

Another key factor is that the cement and aggregate are inorganic, which means they won't burn. Unlike wood, there's nothing there to fuel the flames. This is a crucial difference between cement board and many other building materials.

Even at incredibly high temperatures, while some boards might char or discolor on the surface, the core structure stays intact. This maintains its strength and provides that critical barrier against the spread of fire.

Thickness and Manufacturing Matter

The thickness of the cement board matters too. Think of it this way: a thicker castle wall takes longer for an enemy to breach. Similarly, a thicker cement board withstands higher temperatures for longer. Choosing the right thickness is crucial, especially for applications with strict fire safety requirements.

The manufacturing process also impacts how well a cement board resists fire. Different manufacturers use different formulas and curing processes, leading to variations in density and porosity. These differences can affect how well the board absorbs heat and holds up structurally during a fire. Picking a reputable manufacturer with a history of quality and rigorous testing is essential for dependable fire protection.

Cracking The Code: Fire Ratings Made Simple

Fire safety ratings can feel like a secret language, but understanding them is essential for making smart decisions about your building project. Let’s break down the Australian fire standards and translate them into practical knowledge you can actually use. This guide will help you understand Bushfire Attack Level (BAL) ratings, interpret test results, and see through marketing hype.

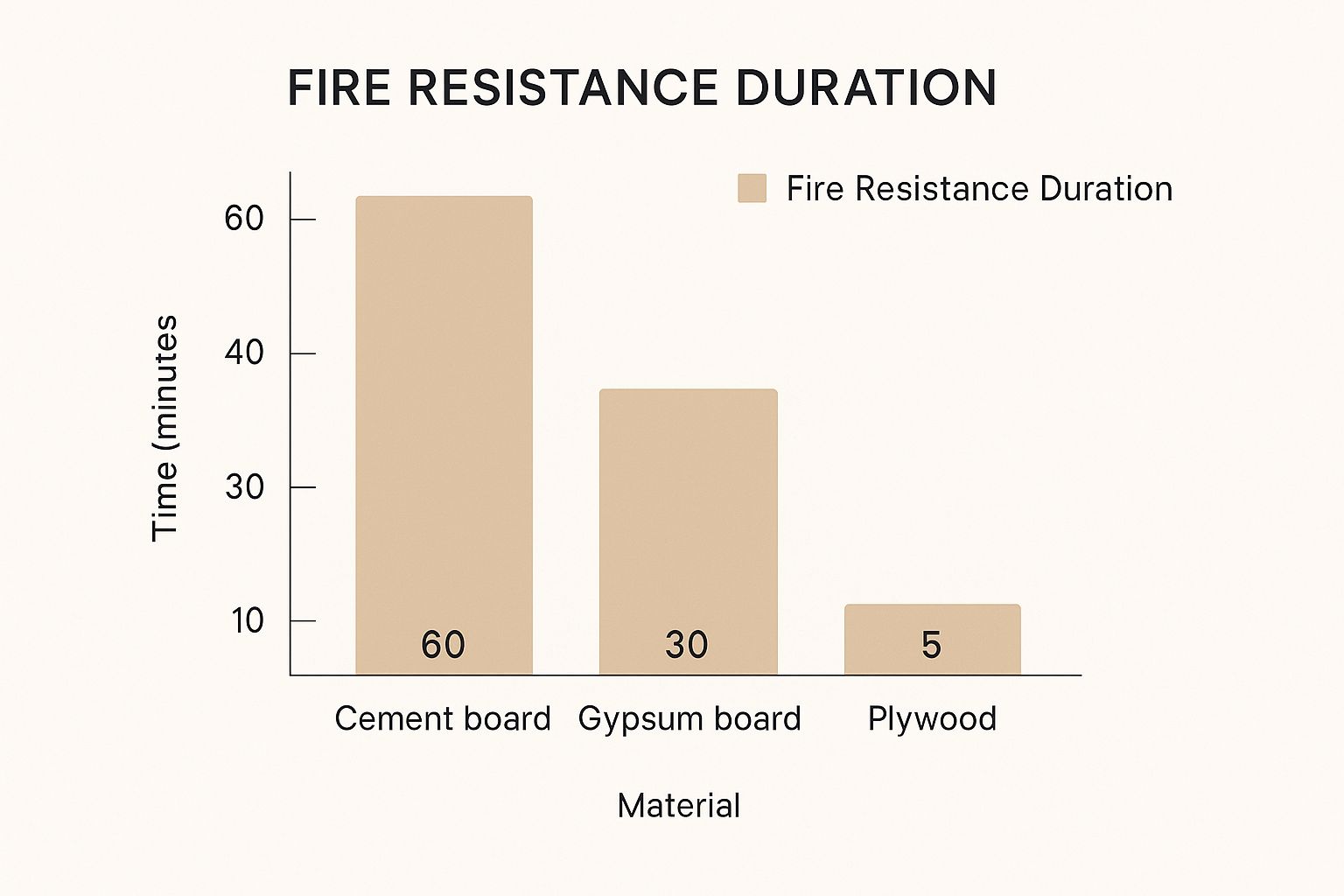

The chart above visualizes how long common building materials can resist fire. Notice how cement board offers significantly longer protection than materials like gypsum board or plywood. This extra time can be the difference between escape and tragedy, giving occupants precious minutes to get out and firefighters more time to control the blaze.

Understanding BAL Ratings

Imagine you’re building a house in Australia. One of the first things you need to understand is the Bushfire Attack Level, or BAL, rating. Think of it as a risk assessment for how likely your property is to be affected by a bushfire.

BAL ratings run from BAL-LOW (minimal risk) to BAL-FZ (flame zone, the highest risk). Each level comes with specific construction requirements to lessen the danger. A house in a BAL-FZ zone, for example, needs much more serious fire protection than a house in a BAL-LOW zone. Knowing your property’s BAL rating is the foundation for choosing the right fire-resistant materials.

Decoding Fire Resistance Tests

How do we know how well a material stands up to fire? We test it, of course! One crucial test measures how long a material can withstand fire before it fails – basically, how long before it loses its structural integrity. This is often measured in minutes.

For instance, a 60-minute fire-rated cement board can hold its own against fire for a full hour. Another vital factor is how well the material stops flames from spreading. This is key to containing a fire and stopping it from consuming the entire structure.

Avoiding Marketing Pitfalls

Let's be honest, marketing can be tricky. Some manufacturers use terms like “fire-retardant,” which sounds impressive but doesn’t tell you much about the actual fire resistance. Don’t fall for vague claims!

Always look for concrete certifications and test results from trusted sources. For example, check if a product complies with the Australian Standard AS 1530.1 (AS 1530.1), which sets out methods for testing the fire resistance of building materials. Verify the data, don't just take their word for it. This careful approach will help you get the protection you need and avoid wasting money on materials that don't live up to the hype.

To help you compare different fire resistance ratings, their uses, and performance needs for cement board, take a look at the table below:

Australian Fire Resistance Ratings Comparison

| Rating Level | Fire Resistance Duration | Typical Applications | Temperature Resistance |

|---|---|---|---|

| FRL 1/2/– | 30 minutes | Walls, ceilings, and partitions in low-risk areas. | Up to a specified temperature limit for 30 minutes. |

| FRL 1/2/4 | 60 minutes | Walls, ceilings, and structural elements in moderate-risk areas. | Up to a specified temperature limit for 60 minutes. |

| FRL 2/2/4 | 120 minutes | Load-bearing walls, fire-rated shafts, and high-risk applications. | Up to a specified temperature limit for 120 minutes. |

| FRL 4/4/4 | 240 minutes | Critical infrastructure, firewalls, and areas requiring maximum fire protection. | Up to a specified temperature limit for 240 minutes. |

The table summarizes how different FRL ratings relate to fire resistance duration, where they're typically used, and their temperature resilience. Choosing the correct FRL rating is crucial for meeting building codes and ensuring adequate fire safety. By understanding these aspects of fire ratings, you can make informed choices, build with confidence, and safeguard your project against the devastating effects of fire.

Where Cement Board Fireproof Materials Shine Brightest

Not every building needs the same level of fire protection. Knowing where cement board truly shines can save you money and maximize safety. Let's explore the most effective uses, from protecting homes against bushfires to creating internal fire barriers.

External Cladding: A Frontline Defence

Imagine your home in a bushfire-prone area. The exterior is the first line of defence, like a castle wall against an invading army. Cement board cladding provides that robust shield against intense heat and embers – think of it as armour for your house. This is especially vital in BAL-FZ (Flame Zone) areas, where direct flame contact is a very real danger. Cement board creates a barrier, drastically reducing the risk of ignition.

Internal Fire Barriers: Containing the Threat

Inside your home, cement board can create crucial fire-rated compartments. These compartments act like firebreaks in a forest, slowing the spread of flames and smoke. This gives occupants precious time to escape and firefighters valuable time to arrive. Think of common applications like the wall separating your garage from your living space or the protection surrounding your stairwell – a vital escape route.

Fire-Rated Shafts: Protecting Vital Services

Buildings have vertical shafts that house essential services like electrical wiring, plumbing, and ventilation. But these shafts can act like chimneys in a fire, rapidly spreading flames upward. Lining these shafts with cement board creates a protective barrier, stopping fire from using these vulnerable channels to spread. This protects the building's structure and the vital services inside.

Innovative Applications: Thinking Outside the Box

Smart builders are always finding clever new uses for cement board. Picture a fire-resistant box built around an outdoor barbeque area, minimizing the risk of fire spreading to the house. Or imagine a protective layer of cement board under decking in a bushfire zone, shielding combustible materials. These innovative applications demonstrate cement board's versatility in boosting fire safety. The Australian cement board market is booming, having reached 12.60 million square metres in 2024. This reflects a growing need for durable, fire-resistant materials. The market is expected to hit 19.95 million square metres by 2033, showing increased awareness of fire safety in construction. Discover more insights

Avoiding Costly Mistakes: Getting the Most From Your Investment

While cement board is a fantastic fireproofing material, improper installation can undermine its effectiveness. A common mistake is inadequate sealing of joints, creating gaps where flames and embers can penetrate. Another error is improper fixing, which can compromise the fire barrier. Following manufacturer guidelines and hiring experienced installers is essential for top performance. Understanding fire ratings can involve SEO considerations, like using a good SEO checklist for blog posts. By understanding the best ways to use cement board, you can ensure effective fire protection and manage costs wisely.

Installation Secrets That Make All The Difference

Even the highest quality cement board fireproof materials can fall short if not installed correctly. These oversights often remain hidden until a fire occurs. This section sheds light on the trusted installation techniques used by experienced contractors. We'll explore proper joint sealing, fixing methods that prevent thermal bridging, and other seemingly small details that can make or break your fire protection strategy.

Sealing Joints: The Critical Link

Think of your cement board joints as the mortar between bricks in a wall. If the mortar is weak, the entire structure is compromised. Similarly, if these joints aren’t sealed correctly, they become entry points for flames and heat. That’s why understanding the crucial role of joint sealant is so important.

Experienced installers know this well. They rely on specific techniques and materials to achieve a robust fire-resistant seal.

-

Fire-rated sealant: This isn’t your average caulk from the local hardware store. Fire-rated sealant reacts dynamically to high temperatures by expanding and creating a fire-resistant barrier. It’s like having a dynamic shield that automatically strengthens under pressure.

-

Proper application: Getting the right amount of sealant is a balancing act. Too little, and gaps will remain, offering an invitation to fire. Too much, and it can crack and fail, defeating the purpose. The key is to carefully follow the manufacturer's instructions.

-

Overlap and embed: For the strongest possible seal, the cement boards should overlap slightly, and the sealant should be embedded within the joint, not just smeared on the surface. This creates a lock-tight barrier.

Fixing: More Than Just Nails

The method you use to fix the cement board is just as important as the sealant itself. Incorrect fixing can lead to thermal bridging, which acts like a thermal highway, allowing heat to bypass the fire barrier through the fixings themselves.

-

Correct fasteners: Using the specified type and length of screws or nails, as recommended by the manufacturer, is essential. The wrong fasteners are like using weak links in a chain – they compromise the entire system.

-

Spacing matters: Proper spacing prevents warping (if the fasteners are too far apart) and weakening of the material (if they're too close together). It's about achieving a Goldilocks "just right" scenario.

-

Avoid over-driving: Driving fasteners too deep can damage the board and reduce its fire resistance. It's like creating puncture wounds in your armor.

Climate Considerations: Adapting to Australian Conditions

Australia’s diverse climate presents unique challenges, and your installation should take these into account.

-

Expansion gaps: In hotter climates, cement board can expand. Leaving small expansion gaps allows for this natural movement, preventing buckling and cracking. Think of it as giving the material room to breathe.

-

Moisture protection: In humid environments, moisture can damage the back of the cement board. A moisture barrier acts like a raincoat, shielding the board from moisture absorption and subsequent damage.

The Devil Is in the Details

Overlooking seemingly minor details can significantly impact the overall fire performance of your cement board. Here are some common pitfalls to be aware of:

-

Damaged boards: Before installation, inspect each board meticulously. Even small cracks can compromise fire resistance. Don't hesitate to reject any damaged boards.

-

Incorrect cutting: Improper cutting creates jagged edges that weaken the board and make sealing difficult. Use the appropriate tools and techniques to ensure clean, precise cuts.

-

Ignoring manufacturer's instructions: The manufacturer has rigorously tested their products and provides specific installation guidelines for optimal performance. Following these instructions isn't just a suggestion, it's crucial.

By paying attention to these installation secrets, you can ensure your cement board fireproof system performs as intended, providing the protection it promises. Remember, proper installation significantly enhances fire performance, while shortcuts can negate the benefits of even the most premium materials.

The Great Material Showdown: Cement Board Vs Everything Else

So, you’re thinking about fire-resistant materials for your next project? Let's compare cement board with other popular options – not with marketing jargon, but with a practical, Aussie-focused perspective.

Cement Board vs. Steel Framing

Imagine steel framing as the bones of a building – strong and fire-resistant. But steel can be pricey and, like a metal frying pan handle, it conducts heat. This can spread fire to other areas. Cement board, on the other hand, is like a protective shield. It's more budget-friendly and doesn’t transfer heat the same way. Remember though, steel is structural, while cement board is typically cladding or a fire barrier. They often work together, not in competition.

Cement Board vs. Fire-Rated Plasterboard

Fire-rated plasterboard is like a common indoor plant – it does a good job and is easy to manage. It offers decent fire resistance and is simple to install, making it popular for internal walls and ceilings. But it's not as tough as cement board and can be prone to moisture damage, a big concern in our diverse Australian climates. Cement board thrives in wet areas and outdoors, where plasterboard would struggle.

Cement Board vs. Mineral Wool Systems

Think of mineral wool as a thick winter coat for your house – excellent insulation and fire resistance. However, it needs careful installation and can be bulky. Cement board, while not as insulating, is a slimmer fire barrier, perfect when space is tight. Combining the two is like layering – mineral wool for warmth and cement board for a tough, fire-resistant outer layer.

Hybrid Approaches: The Best of Both Worlds

Just like a balanced diet is best for your health, using a mix of materials is often the smartest building approach. You might use steel framing for structure, mineral wool for insulation, and cement board for a fire and weather-resistant exterior. This allows you to maximize the benefits of each material.

Speaking of cement board, the Australian market is predicted to grow significantly, reaching USD 442.5 million by 2030, with a CAGR of 15.1% from 2023 to 2030. Interestingly, high-density cement board dominated in 2022, holding a 61.58% market share. Discover more insights. For specific product details, you might find this concrete board product interesting.

This targeted combination of materials can create a more cost-effective and high-performing building over time. The key isn't about finding one "super-material," but choosing the right materials for your specific project and budget.

To illustrate the differences, let's take a look at the following table:

Fireproof Material Performance Comparison: Side-by-side comparison of cement boards against other common fireproof building materials including cost, fire rating, and installation complexity

| Material Type | Fire Rating | Cost Per Square Metre | Installation Difficulty | Durability Score |

|---|---|---|---|---|

| Cement Board | Up to 2 hours | $20 – $40 | Medium | 9/10 |

| Steel Framing | Up to 4 hours | $50 – $80 | High | 8/10 |

| Fire-Rated Plasterboard | Up to 1 hour | $10 – $20 | Low | 6/10 |

| Mineral Wool Systems | Up to 4 hours | $30 – $50 | High | 7/10 |

As you can see, each material has its own strengths and weaknesses. Cement board offers a great balance of fire protection, cost-effectiveness, and durability. While steel provides the highest fire rating, it comes at a higher cost and installation complexity. Fire-rated plasterboard is the most affordable and easiest to install, but it lacks the durability of cement board. Finally, mineral wool provides excellent fire resistance and insulation, but installation can be challenging.

This comparison highlights the importance of considering all factors when choosing a fire-resistant material. Your specific needs will determine the best option for your project.

Your Fire Protection Action Plan: Making Smart Decisions

Building with fire-resistant materials like cement board is essential. But it's just one piece of a larger fire protection strategy. Think of it like building a castle. Strong walls are important, but you also need moats, gatehouses, and vigilant guards. Similarly, a comprehensive fire protection plan needs careful thought from assessing the initial risks to the final installation. This guide will give you the knowledge to make informed choices, create a realistic budget, and ensure your project offers genuine protection.

Assessing Your Risk: Knowing Your Battlefield

Before choosing materials, you need to understand your specific risks. It's like scouting the terrain before a battle. Is your property in a bushfire-prone area? What's your Bushfire Attack Level (BAL) rating? This rating is your starting point. A high-risk area (BAL-FZ, for instance) demands a very different strategy than a low-risk location.

For more information about building material choices, take a look at our guide on where to buy stacked stone veneer. This risk assessment informs your entire plan, from choosing materials to deciding on installation methods.

Budgeting Wisely: Investing in Protection

Fire protection is an investment, not an expense. It's similar to insurance—you're paying now to protect yourself from a potentially devastating event down the road. While premium materials like cement board might have a higher upfront cost, the long-term savings can be substantial. Imagine the cost of rebuilding after a fire, not to mention the emotional impact.

Your budget should include not only the material costs but also the installation. Correct installation is crucial for effectiveness. Cutting corners can negate the benefits of using high-quality materials. A well-planned budget covers everything: materials, labor, permits, and inspections.

Choosing the Right Materials: Building Your Defenses

After assessing your risk and setting a budget, you can choose your materials. Cement board is a great choice for various applications, especially external cladding and internal fire barriers. Compare its strengths against other fire-resistant materials, like steel, plasterboard, and mineral wool. This will help you find the right balance of performance and budget.

Different applications might require different materials or combinations of materials. For example, you could use steel for framing, mineral wool for insulation, and cement board for cladding. Each material plays a unique role in your overall fire protection strategy.

Installation: The Final Piece of the Puzzle

Even the best materials won't work if they're not installed correctly. It's like a suit of armor—if it doesn't fit right, it won't protect you. This is where experienced installers are essential. They understand proper joint sealing, fixing patterns, and other critical details. These details ensure your fire protection system works as intended. Always follow manufacturer instructions and use the right tools and techniques.

Ongoing Maintenance: Keeping Your Guard Up

Fire protection isn't a one-time thing. It requires ongoing attention. Think of it like keeping your castle defenses in top shape. Regular inspections can catch small problems before they become big ones. Check for damage, weathering, and other signs of wear and tear. Proper maintenance ensures your fire protection system remains effective for years to come, offering lasting peace of mind. For expert advice, free quotes, and a range of sustainable, high-quality building materials, visit Flomary Group. We can help you build with confidence and security.